Group Sustainability

Philip Payne, as part of the FW Thorpe Group of companies, is committed to minimising the environmental impact of its activities across all operations.

The FW Thorpe Group of companies has been officially recognised as being carbon neutral*, with systems of reduction, measurement and certified offsetting in place, since 2012. Third party assessment provides independent assurance of the Group’s long-standing commitment to sustainability across all of its operations worldwide. Being carbon neutral means that FW Thorpe Plc offsets the carbon dioxide emissions it generates (scopes 1 and 2 of the Greenhouse Gas Protocol) by its business activities.

FW Thorpe Plc is a carbon neutral company through a combination of measures. Company-wide initiatives such as energy use minimisation, self-generation of renewable energy through solar photovoltaic (PV) units, and procurement of renewable energy have reduced the Group’s carbon footprint, whilst trees in the Group’s award-winning carbon offsetting afforestation project absorb the remaining carbon dioxide produced.

The goal is ultimately to reach net-zero in 2040, ten years before the UK’s target for achieving net-zero greenhouse gas (GHG) emissions by 2050.

In 2022, FW Thorpe initiated a robust data collection process to calculate its full carbon footprint, extended to include upstream and downstream activities – for example those throughout its supplier and customer relationships. The Group’s carbon emission reduction plan is aligned with the Paris Agreement 1.5°C scenario (reactive) and its full Scope 1, 2 and 3 emissions for the 2021 base year, 2022, and the current financial year 2023 have been calculated.

Emission reduction targets

FW Thorpe has set and submitted the following Science aligned targets for validation by the Science Based Targets Initiative:

- Reduce absolute Scope 1 and 2 emissions by 42% by 2030, from a 2021 base year on a market-based approach.

- Reduce Scope 3 emissions per £m revenue by 51.6% by 2030, from a 2021 base year.

- Reduce Scope 1, 2 and 3 emissions by 90% by 2040 from a 2021 base year, in line with reaching net-zero with a maximum of 10% of emissions being offset.

*Group companies acquired since 2012 have been assessed only since their date of acquisition.

Sustainability Actions

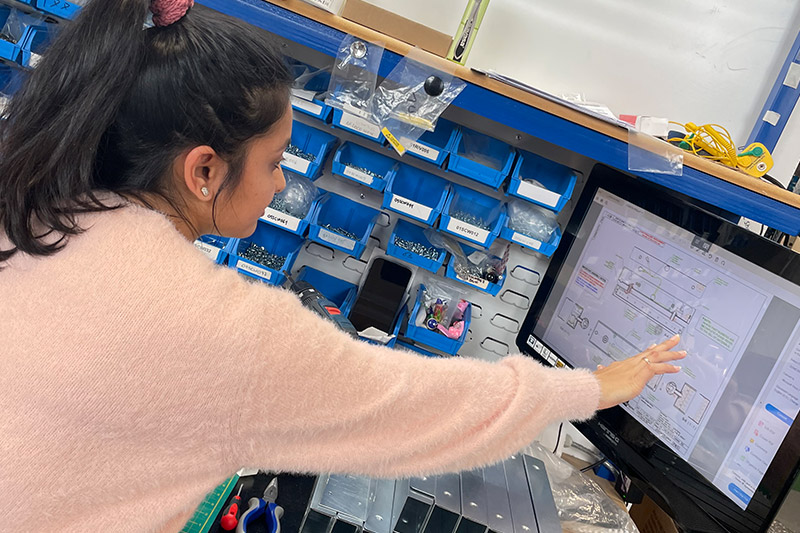

Manufacturing Excellence

Philip Payne is proud that around 97% of its products are manufactured in the UK. This enables the company to meet urgent customer demands without the need to transport products by air, which would involve additional financial and environmental costs.

Philip Payne designs and manufactures its luminaires to the highest standards, ensuring optimal performance and reliability. All luminaires are covered by a 6 year warranty (including batteries). Customers can therefore purchase Philip Payne luminaires with even more confidence.

Waste Management

The manufacturing process is constantly monitored to improve resource efficiency and reduce waste. Any waste generated, including end-of-life components, is subject to ethical disposal or recycling.

Philip Payne is fully aware of its responsibilities to discharge its obligations under the UK WEEE regulations 2006 (SI3289) and the EC WEEE directive. The Philip Payne WEEE Producer Registration is WEEE/DK0073UQ and the company is registered with the Lumicom Compliance Scheme (www.lumicom.co.uk).

Transport

65% of Philip Payne company cars are either hybrid or full electric vehicles (EVs) and the company has a proactive policy in place to increase their use.

Philip Payne products are distributed via a national carrier service rather than its own fleet. Deliveries are collected once daily from our factory in Solihull and sent to a local hub, sorted and forwarded to other regional hubs around the UK, so minimising specific journeys.

Packaging

Philip Payne is working to eliminate plastics, increase recycled content and reduce overall packaging.

All cardboard packaging is made from recycled sources and recycled on site. Vinyl-based packaging has also been replaced with paper-based tape.

Philip Payne has moved from paper to digital installation guides. By scanning a QR code on either the packaging or the product users have access to installation information.

All printed product literature is made of material from well-managed, Forest Stewardship Council (FSC)-certified forests and other controlled sources.

All unwanted Philip Payne documents and correspondence are shredded for use in product packaging. Incoming packaging and pallets used in production are recycled where possible for further use.

Carbon Offsetting

In 2009, FW Thorpe Plc purchased 215 acres of farmland in Wales. To date, 179,412 trees have been planted for carbon sequestration. Based on the Group’s calculated emissions, it has been confirmed that enough trees have been planted for FW Thorpe Plc to have been carbon neutral since 2012.

The carbon capture tree-planting scheme (quality-assured by the government-backed Woodland Carbon Code) is independently certified to ISO 14064-3 and ISO 14065 standards. The Woodland Carbon Code is an independent standard, devised by a group led by the UK Forestry Commission, to certify that woodland creation projects can accurately measure how much carbon is captured and stored.

FW Thorpe has completed its woodland creation project in Devauden, Wales and has recently purchased a further 195 acres of land in Herefordshire. The land has significant potential for connecting existing woodlands for biodiversity and landscape enhancement and the transition from grazing sheep to woodland creation will have little to no impact on food security.

Employee Engagement

Philip Payne employees are encouraged to share their ideas for green initiatives and post them in the suggestion boxes located on site.

Every 6 months the FW Thorpe group recognises, with an award, the employee who has made the most interesting sustainability suggestion.

Our Future Plans

Company Targets

Philip Payne is committed to addressing the sustainability challenges of not only today, but also tomorrow. Understanding the needs of customers and stakeholders and the expectations they have is central to ensuring that Philip Payne prioritises the most critical issues and operates a responsible and sustainable business.By assessing the company’s carbon impact right across our manufacturing and value chain then setting science-based targets in line with the Paris Agreement on climate change, the goal is ultimately to reach zero carbon status well before the UK’s target for achieving net zero carbon emissions by 2050.

- New product design is to follow an FW Thorpe Plc agreed Circular Design Strategy, ensuring products last even longer, use sustainable materials in their construction and are easier to reuse, refurbish or recycle at the end of their lifetime.

- Philip Payne will provide electric vehicle (EV) charging stations at the workplace.

- All finished goods packaging is to be supplied from Forest Stewardship Council (FSC) or equivalent sources.

- Philip Payne employees are to be trained in environmental initiatives.

SUSTAINABILITY

SUSTAINABILITY

WARRANTY

WARRANTY

WHY USE...

WHY USE...

NEWS

NEWS

Watch Full Video

Watch Full Video

Chairman's Comment

FW Thorpe Plc has a longstanding commitment to helping tackle global environmental challenges, principally through its core business of manufacturing energy efficient lighting equipment. The company has a genuine desire to become a more sustainable business.

The carbon capture tree-planting scheme (quality-assured by the government-backed Woodland Carbon Code) is independently certified to ISO 14064-3 and ISO 14065 standards. The Woodland Carbon Code is an independent standard, devised by a group led by the UK Forestry Commission, to certify that woodland creation projects can accurately measure how much carbon is captured and stored.

But our work doesn’t stop here. By assessing our carbon impact right across our value chain, and then setting science-based targets in line with the Paris Agreement on climate change, our goal is to further and significantly reduce our impact by the near term target of 2030 followed by ultimately reaching net-zero greenhouse gas (GHG) status by 2040, well before the UK’s target for achieving net zero carbon emissions by 2050.

Mike Allcock

FW Thorpe Group Chairman